The Inconsistent Packaging Problem

KaLaya Health & Wellness

Packaging Amalgamation

Year

2022

Overview

A product packaging redesign to solve multi-level problems in the organization. In collaboration with research & development, production, sales, & marketing departments.

KaLaya Health & Wellness is a brand dedicated to restoring the quality of life for individuals suffering from muscle, joint, and back pain.

My role

In-house Senior Graphic Designer within inter-departmental team.

Responsibilities

- Problem definition

- Research

- Packaging design

- Procurement

Within my first 60 days of starting a new gig, I had frequent weekly inter-department visits at my desk about frustrations with existing product packaging.

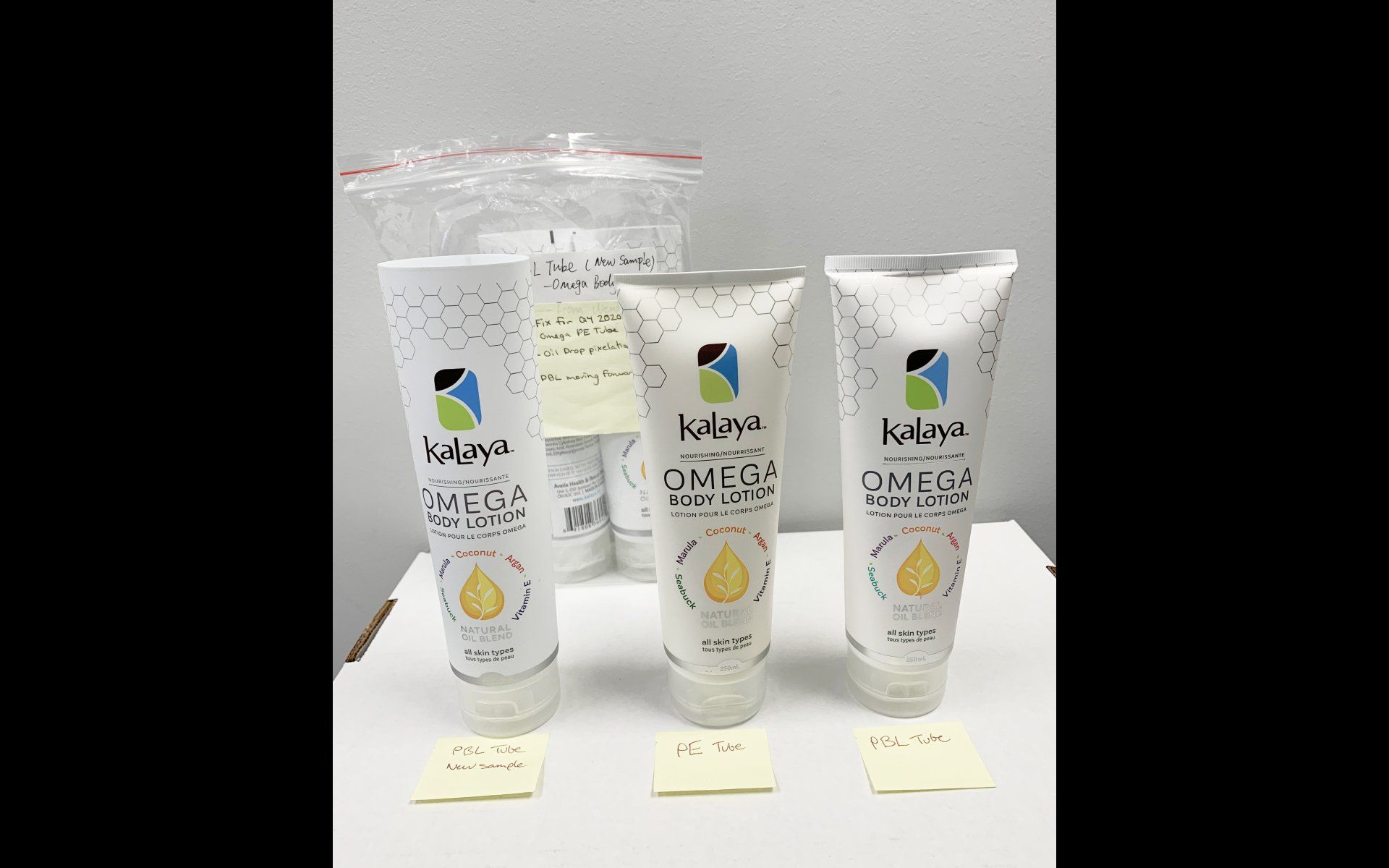

“Why are these two tubes different sizes if its for the same product?!. The packaging operator would ask me with a gruntled puzzled face. “And the new shipment of cartons we received from overseas - half of them are bent - they won’t work on our machine - now we’re forced to fill the cartons manually!”

Being new to the position. I wasn’t aware of why these inconsistencies were occurring. But I could understand the warehouse supervisors frustrations.

I quickly learned that there were pain points in every packaging shipment we received. But Why?

Cartons are shipped from overseas suppliers, when we received them, half of the skids are damaged because of poor shipping practices. Additionally the company pays tens of thousands of dollars in [border] fees.

Oh and colour mismatches of Pantone colours were a regular issue. The amount of different tones for one pantone colour! Wow. Unacceptable. Especially when trying to build brand loyalty.

The plant manager was furious “These cartons are supposed to be white” he would say. “Why is the board so flimsy”.

And the logistics manager. Oh man. I can still hear her stressing about not meeting the production deadline.

Back at my desk, I gazed at the product packages and spun them around from front to back. I thought, “how can we eliminate all these pain points and keep the packaging consistent throughout all skus?”

I set out to interview all parties involved in the manufacturing process. Pick their brain. What’s their challenge, suggestions, see with my own eyes the process of the individual stages involved.

First trip

To the production floor to see the machines in action. My curious eyes saw the tubes get filled with product, the carton assembled, and the filled tubes get stuffed into the cartons. I learned what the carton die needs to be like in order for the machines to run optimally.

Second trip

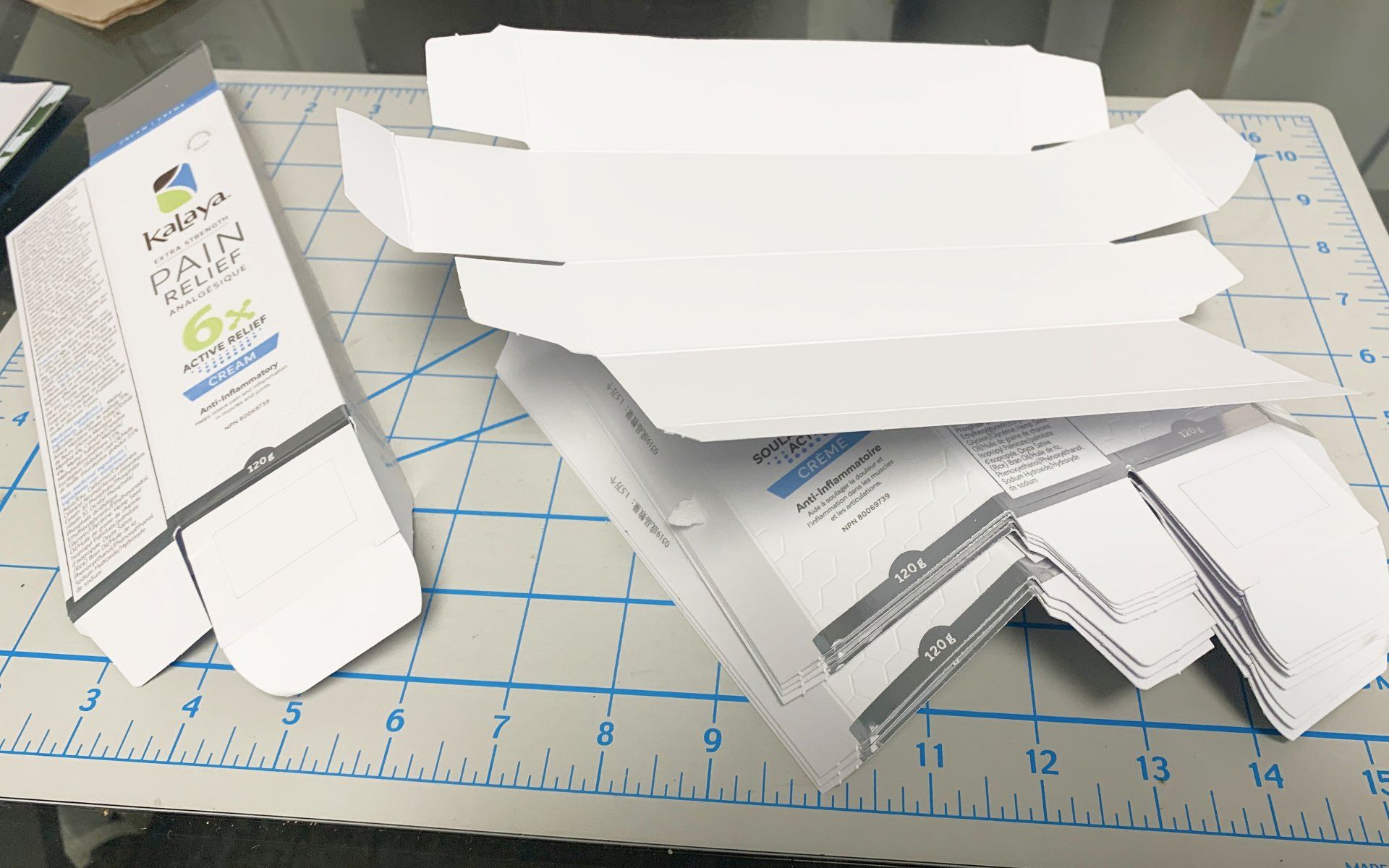

To the warehouse to see the physical state of the shipments. WOW! Ok. They weren’t kidding. The boxes containing the printed cartons within the skid looked like an elephant sat on them. They were bursting from the seams. Very little tape. Soft humid boxes. Uneven stacking. No edge protectors. What a nightmare.

Third trip

A facility tour for a new potential local carton supplier. I witnessed their ink mixing process, creation of dies, printing presses, embellishment stations, cutting, scoring, folding, gluing, and pallet assembly. The whole shah-bang. I was definitely sold. The quality was top notch.

Fourth trip

Brick and mortar store to see the products on the shelves. Our planogram versus the competitors. I wondered. “How can we make adjustments to our packaging while staying within 20% variance.

Fifth trip

The sales directors office. To pitch an idea of making adjustments to existing designs in order to cut costs, increase efficiency, streamline production and assembly, and improve quality of packaging. Yep, he was on board. I also learned the important limitations to be mindful of.

Sixth trip

My desk with all the existing packaging and my new found knowledge and insights. The sketchbook started filling up with quick concepts, math calculations, suppliers costs, learnings, insights, notes, quotes etc. Then aha! Lightbulb.

I eagerly called the new local supplier with my proposed idea for a new carton design. Within days he came and delivered prototype cartons to test. I gathered the team to discuss said prototype. Well received. BUT. It won’t work with the packaging machine. I quickly learned why.

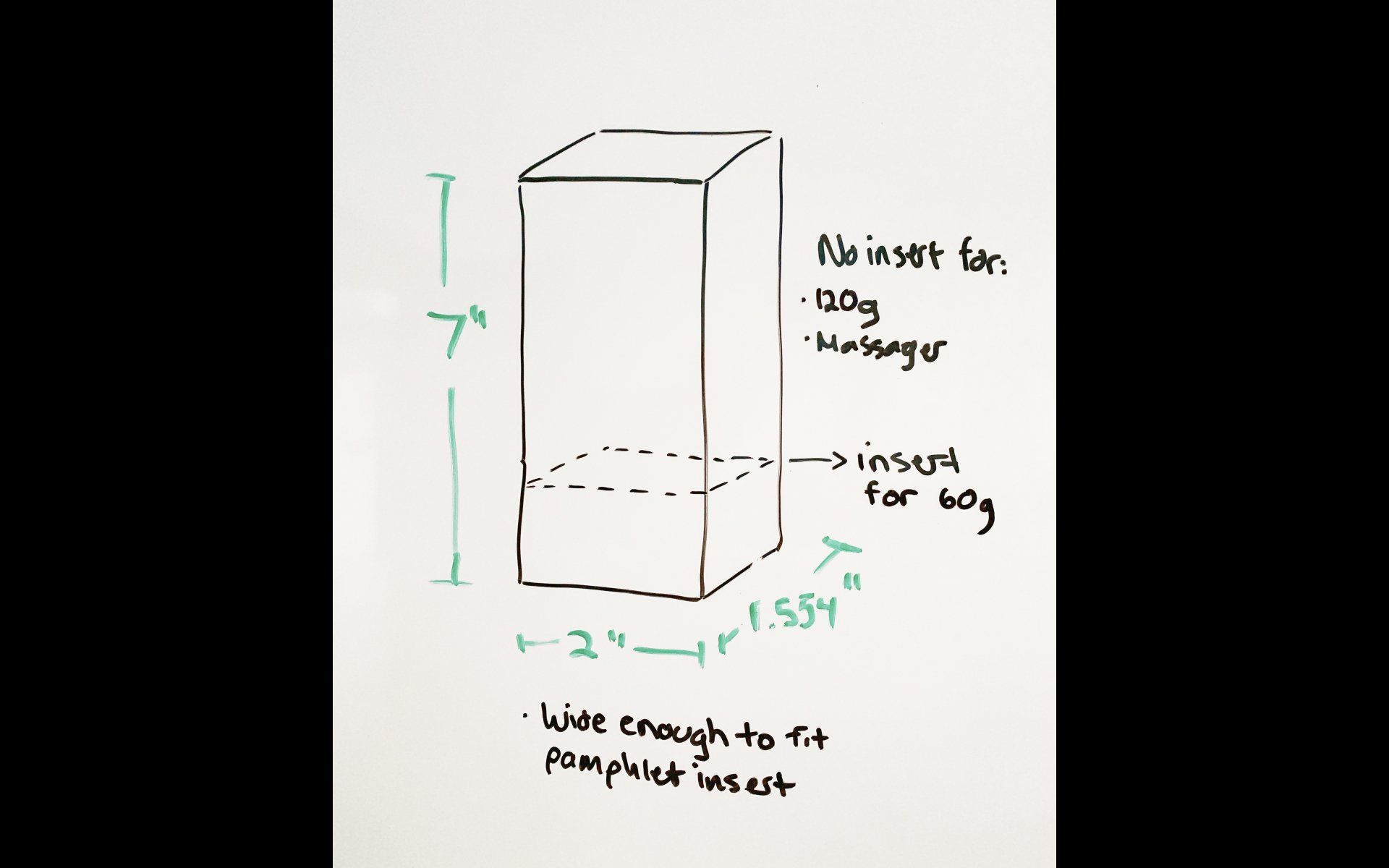

I designed another carton with some adjustments. Prototype was delivered. Boom! Works well with our machines…BUT, a much wanted pamphlet insert won’t fit in the carton with the product inside. “You have to make it wider”, the machine operator proclaimed.

Being mindful of the 20% variance, I adjusted the size dimensions to allow for the product and insert. The new prototype came. Ta-dow! Success.

So now it was time to roll it out for the other products skus being mindful of their unique specifications.

In the end, gathering all the parties involved in the manufacturing process and openly communicating the journey of the packaging amalgamation was essential to have a consistent, premium quality planogram.

The Result

The new cartons saved the company thousands in die costs, tens of thousands in logistics costs, thousands of dollars in manual production time, improved efficiencies, and 30% reduction of time waiting for shipments. Not to mention, a big boost in team morale. The future looks promising.

The Visuals

Tens of Thousands in Savings

Packaging Costs

30% Efficiency

Logisitics

Big Boost

Team morale